CCME & MCPS have over 20 years experience in manufacturing Cathodic Protection (CP) to all sectors and are a Products include:

- Galvanic Anode Cathodic Protection (GACP)

- Impressed Current Cathodic Protection (ICCP)

- Marine Growth Prevention Systems (MGPS)

- Hydro Sonic Antifouling (HSAF)

Anode casting in accordance with:

- DNV-RP-B401

- ISO 15589-2:2004

- NORSOK M-503

Anode inspection requirements conform to:

- NACE Standard SP0387-2006

- NACE Standard SP0492-2006

CCME-MCPS design and manufacture Cathodic Protection Systems that consist of aluminium, zinc and magnesium sacrificial anodes. We have an anode manufacturing facility in Saudi Arabia and Bahrain that can supply quickly by road freight to the Arabian Peninsula with clients in countries such as Kuwait, Oman, Qatar, United Arab Emirates and Yemen also to other emerging markets within the Middle East such as Iraq, Egypt, Libya, Azerbaijan, Kazakhstan and India and even the Far East and African Markets.

Not only do CCME-MCPS have an Anode manufacturing facility but also provide and have the experience in cathodic protection design, supply and installation. This is not something that the existing anode manufacturers offer, nor have experience in.

CCME-MCPS have highly respected Joint Parent companies that already manufacturer and design CP systems to the marine, marine civil, industrial and offshore markets across Europe and the Middle East.

CCME MCPS also own the Z-Guard Anode brand which has been established since 1977. Z-Guard anodes have been supplied across UK, Europe, Africa and the Middle East for over 45 years.

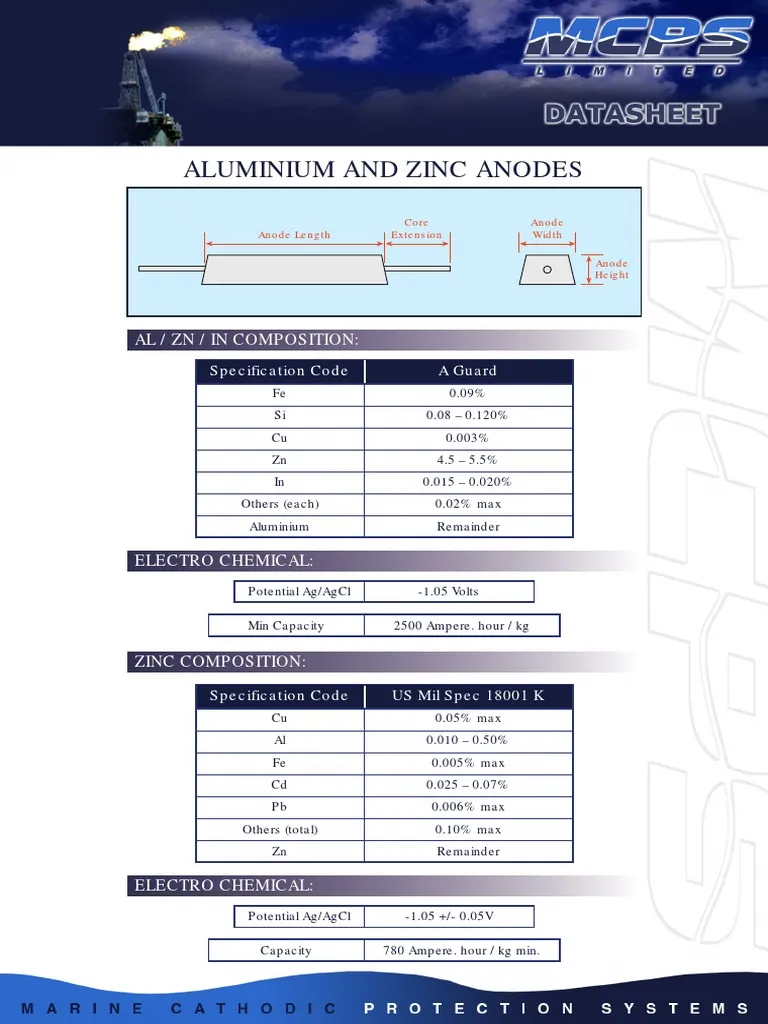

CCME MCPS foundry is ISO 9001:2015 accredited for the manufacture of sacrificial anodes and work in accordance with NACE and DNV RB P401. MCPS’ foundry has DNV type approval for Aluminium Alloy A-Guard ® and CCME-MCPS have Licenses to produce A-Guard®.

Our Products

API 6A MONOGRAM CONNECTIONS TO PLS1, 2 & 3. LICENCE 6A-1792

CCME & Oilquip offer a large range of API 6A monogrammed connectors in Forged high yield and tensile materials such as 4130, F22, Duplex and Super duplex Stainless steels. Connectors typically suit 2” to 6” nominal bore with pressure rating of 2,000 to 20,000 PSI utilized in Choke and kill and wellhead Christmas tree systems.

- API 6A Flanges Blind

- Studded Blocks

- Cross Over

- Adaptors Flanges

- Flanged Spacer Spools.

- Hub & Clamp Connectors

- Figure 1002 & 1502 Hammer Lug Unions

- Manifold Wrought Fittings

- Long Sweep Elbows & Fittings

- ANSI B16.9 Long Radius Elbows & Fittings

- ANSI B16.9 Block Fittings

API 6A VALVES

Valves are available in a variety of sizes from 2”-6” and can also be supplied with flange, hub, hammer unions, threaded or

butt-weld ends. Full material tractability is guaranteed and Sour service valves conform to the requirements of NACE MR- 01-75.

- Gate Valves

- Mud Valves

- Choke Valves

- Plug Valves