CCME can provide a range of products and services to facilitate complete cathodic protection solutions for Industrial systems, offshore systems, Steel in concrete and offshore vessels. This ranging from in plant and cross-country pipelines, external tank bases, tank internals, buried tanks & vessels, trestle & jetty piles, Ships, steel and concrete piles, sheet piles & piers, offshore platforms, submerged structures, and concrete foundations.

Service Offerings

Industry Experience

Some of the industrial sectors and structures to which CCME have successfully provided services and products include:

- Industrial Complexes: Underground Process Facilities, Product Piping, Storage Tanks, Condensers, Water Treatment Equipment

- Oil & Gas Pipelines: Transmission Facilities, Tank Farms, Distribution & Gathering Facilities

- Oil & Gas Production: Refineries, Bulk Handling Plants, Oil Well Casings

- Power Plants: Underground Piping Networks, Ground Grids, Pipeline Corridors, Condensers

- Cooling Water & Treatment Facilities, Underground Structures, Tanks

- Ship Repair Industry: Tanker Hulls, Ballast Tanks

- Offshore: Drilling Rigs, Offshore Pipelines, Marine Terminals, Sheet & Tubular Piles, LoadingUnloading Terminals, Dock Structures, Jetties

- Infrastructure Concrete Industry Projects: Bridges, Docks,, Cooling Towers, Parking Garages, Desalination Plants, Underground Ducts, Buildings, Foundations, Swimming Pools, Aquariums

- Integrity Management: Survey and Evaluation of Pipeline and Plant Facilities

Supply and Installation

CCME can offer complete service for supply and installation of cathodic protection systems and the associated quality assurance, CCME work directly with NACE lvl 4 technologists and industry specialists for design and engineering support where required, CCME can also directly support any site installation with supervision and project management, whilst also having a wide range of trusted subcontractors to carry out any work associated with the successful completion of projects.

Temporary Cathodic Protection

CCME can design, provide and install temporary CP for short term cathodic protection when the permanent ICCP will not be energized for a period of time, this usually during construction or installation of the structure, this is typical via the use of sacrificial galvanic anodes.

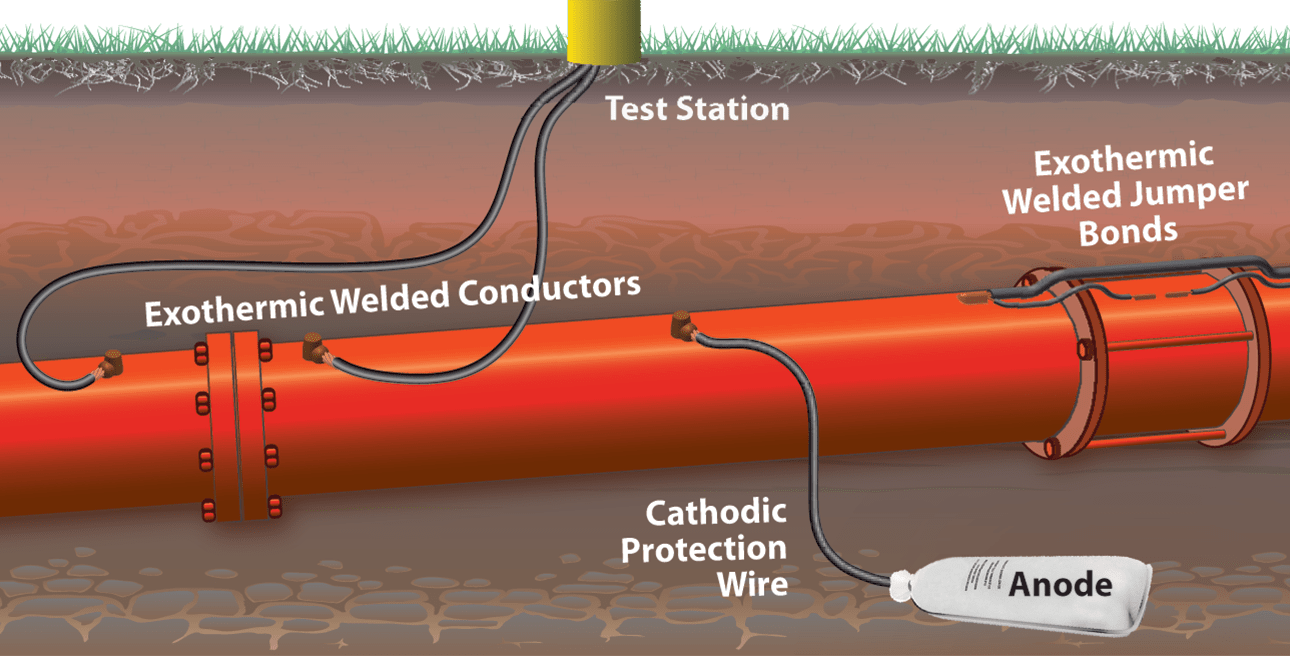

Temporary or permanent junction box or test station facilities can be used to terminate the supplemental galvanic anodes enabling pipe-to soil potential survey data verifying that the temporary system is providing adequate protection.

Permanent Cathodic Protection

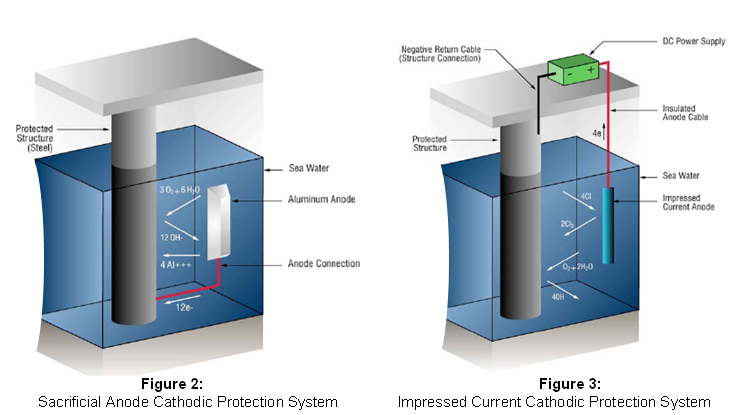

CCME can design, provide and install both methods used for applying permanent cathodic protection to buried or immersed structures

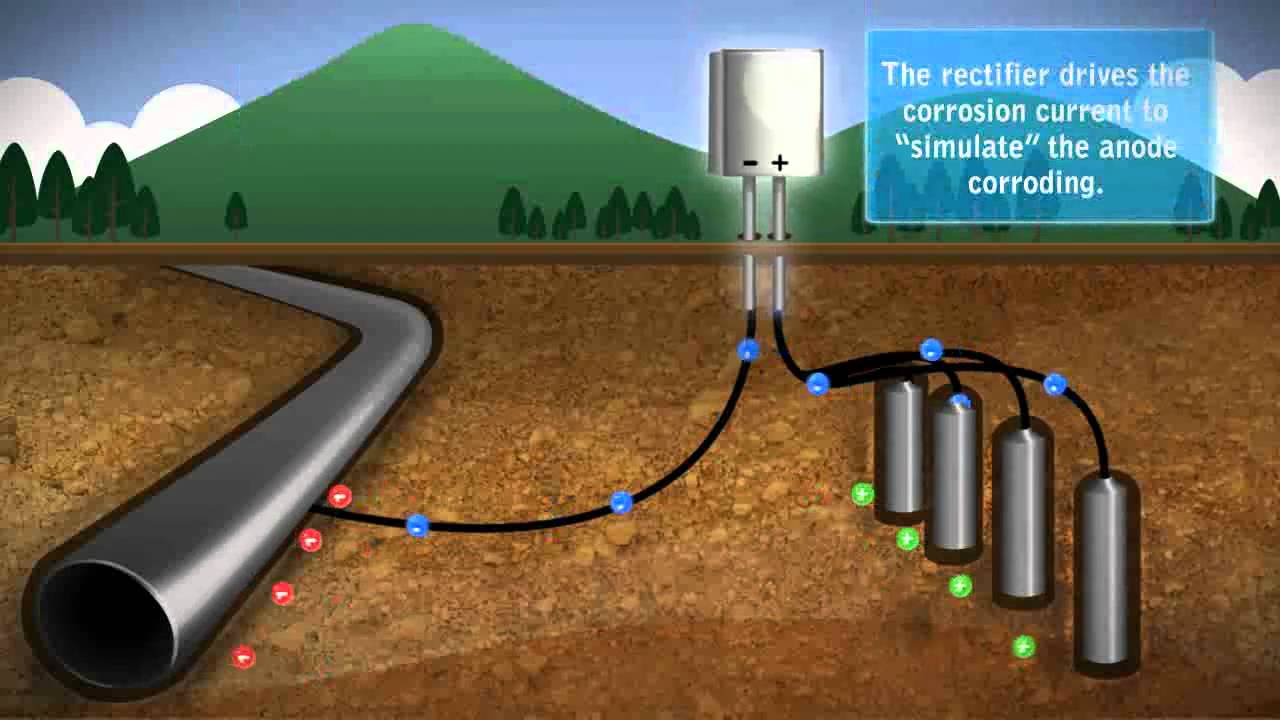

Galvanic anodes to utilize the potential difference between the pipeline steel and the more active anode material to provide the driving voltage, and the Impressed current system utilising an external DC voltage source to drive the current through relatively inert anodes.

Cross-Country Pipelines and Buried Structures

CCME can provide pre-design surveys, specialized surveys, supply of materials, design, installation, interaction testing, commissioning, monitoring and trouble shooting for cross country pipeline cathodic protection solutions.

Our company can offer complete cathodic protection systems for pipelines utilizing either impressed current or galvanic anode type systems or a combination of both types. Impressed current CP stations can be designed to protect large portions of underground piping depending on coating quality and pipe diameter. On shorter pipelines galvanic anodes are commonly installed.

In addition, CCME can offer complete solutions for other buried structures such as deep well casings, culverts and steel piling.

Submerged Offshore Structures, Pipelines And Harbour Facilities

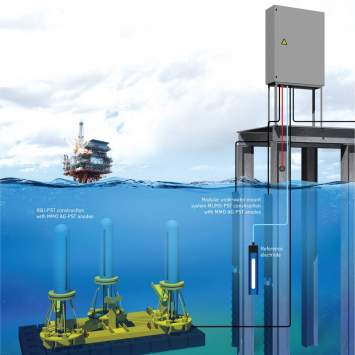

CCME work closely with Marine contractors and can facilitate and manage entire projects for Submerged structures. Our company can offer complete cathodic protection solutions for steel structures in sea water which can be effectively protected by both impressed current and galvanic anode systems. These cathodic protection systems require a large current capacity and the anode systems need to be sufficiently robust to withstand all sea conditions and are typically designed to operate for at least 30 years with minimal maintenance requirements.

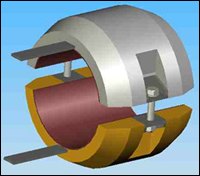

CCME can also offer offshore flush mounted sacrificial anodes along with their installation and subsequent commissioning. These anodes being either half shell or segmental bracelet anodes.

Our company can also offer impressed current systems for shorter pipelines where the Transformer Rectifiers are located at the shore and/or the platform. Our harbor facilities cathodic protection systems include steel sheet piling, tubular piled jetties and outfall pipelines

The cathodic protection systems can employ either directly mounted or remote anodes of either impressed current or galvanic type. Cathodic protection systems are designed bearing in mind tidal movements and changes in salinity that will occur, so that sufficient current is always supplied for protection.

Internal Surfaces of Vessels

CCME offer corrosion solutions for internal vessels. Whilst external surfaces are often contained in large electrolytes, e.g. the sea, the internal surfaces are not.

Cathodic protection is used where there is limited space for locating anodes, CCME can offer systems can be produced to accommodate this with either sacrificial or impressed current cathodic protection.

Marine Sector

CCME MCPS has over 20 years manufacturing and design experience and is a leading supplier of Cathodic Protection (CP) and Marine Growth Prevention Systems (MGPS) to Marine Ship Owners, Offshore Energy and Port Markets.

This high level of experience ensures that CCME MCPS fully understands and can supply corrosion and anti-fouling prevention equipment in accordance with the most stringent requirements as demanded by our market sectors.

For your Aluminium (Al-Zn-In) and Zinc Galvanic Anodes, Impressed Current Cathodic Protection (ICCP) and Marine Growth Prevention System to prevent Antifouling please contact us at your convenience for an efficient and competitive quotation.

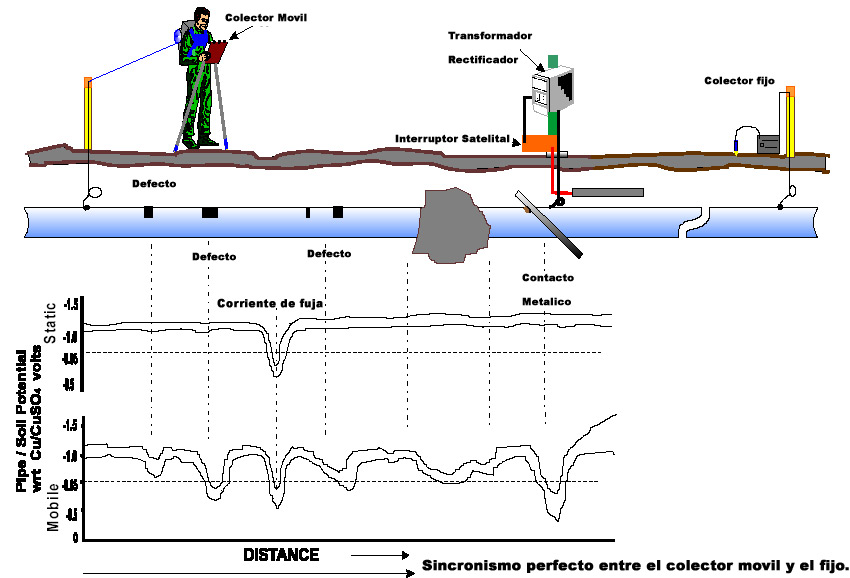

Close Interval Potential Surveys CIPS

CCME offer CIPS (Close Interval Potential Survey’s) or ‘Over-Line Surveys monitor pipe to soil potential values along the route of a buried pipeline at ‘small’ intervals, typically 1-2m thereby providing a complete assessment of the level of CP applied to a pipeline in comparison to recognized criteria.

Periodically CCME perform close interval surveys for various clients to ensure the entire pipeline is within the protection criteria. The exact route of the pipeline is followed using pipe location equipment so that the survey operator can record accurate data.

The profiles of the pipe to soil potentials and static reference potentials recorded are analyzed simultaneously to determine the CP levels against known criteria. Areas of under protection can be identified and possible coating defects can also be highlighted. Areas of stray current interference can also be depicted.

DCVG Surveys

CCME carry out DCVG Surveys to locate external coating defects on buried pipelines. Defects are determined from the Voltage gradients generated from the flow of DC current from a CP System to the defect positions.

Defect sizes are estimated against the IR drop determined at the defect position and are generally referred to as percentages. CCME then recommend repair work based on the analysis of data from the survey.

Monitoring

CCME offer Routine monitoring activities and are scheduled for various frequencies and scopes of work. Typically our company offers monthly inspections of CP systems inclusive of the following

- Visually inspect transformer-rectifier and record dc output Voltage and output current.

- At drain points record pipe to soil potential and where installed coupon ‘ON’ and ‘instantaneous OFF’ potentials.

- Measure and record structure to soil potentials at all available test facilities

- Record ‘ON’ and ‘instantaneous OFF’ potentials on all buried coupons.

Recommendations are subsequently made based on the analysis of system performance and CCME offer complete solutions for rectifying any issues with the cathodic protection systems.